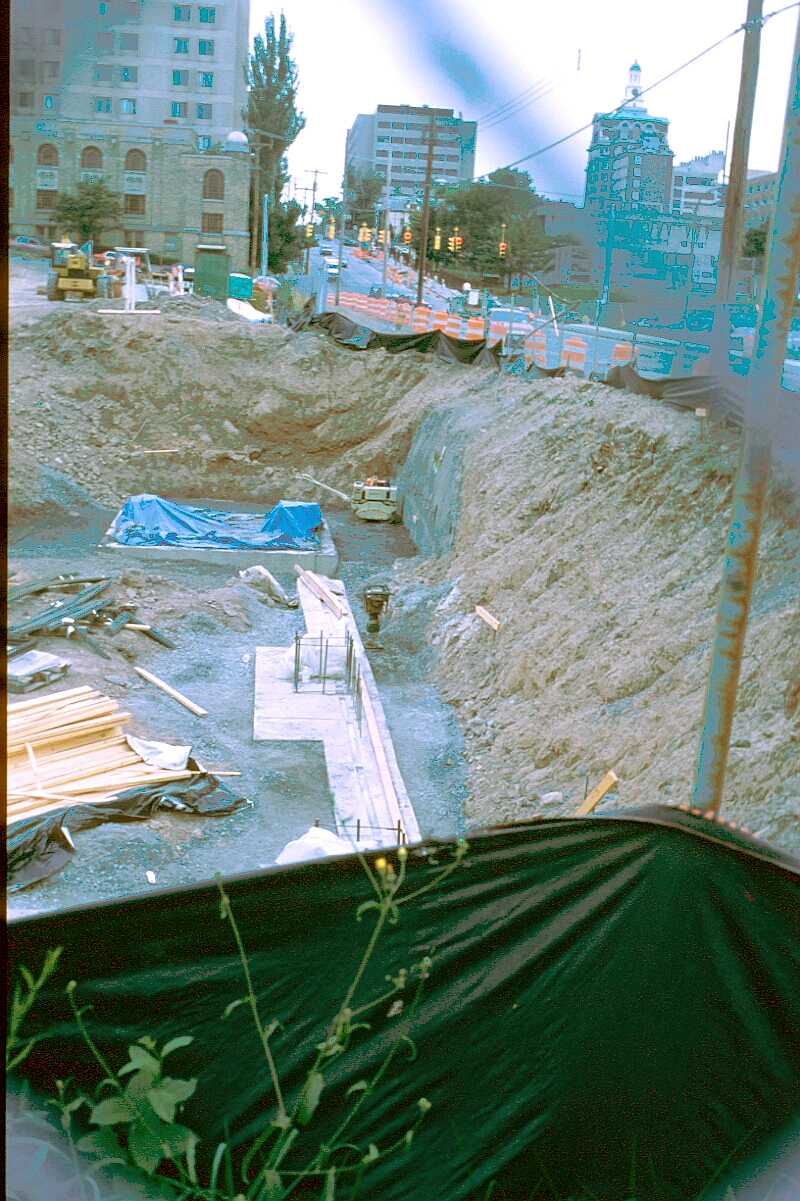

image 14: Backfill and compaction procedures.

Division 2 - Site Work

Section 02200 - 3.09-15 Backfill

and Compaction

image 14: Backfill and

compaction procedures.

Image 14 shows two different types of compacting machines. The one towards the back near the tieback wall is a vibrating roller, and the one forward is a reciprocating tamper. Both are used as required by site restrictions to accomplish compaction of backfill material in this image, against footing sides and grade beams. Compaction must be accomplished in layers, "lifts" of no more than 8". The specifications call for the compaction of loose material to achieve a compacted condition of 95% of that materials natural density in an unexcavated condition. To insure this specification, an independent testing agency is hired by the Owner, and approved by the Structural Engineer, to oversee the backfill and compaction procedure.

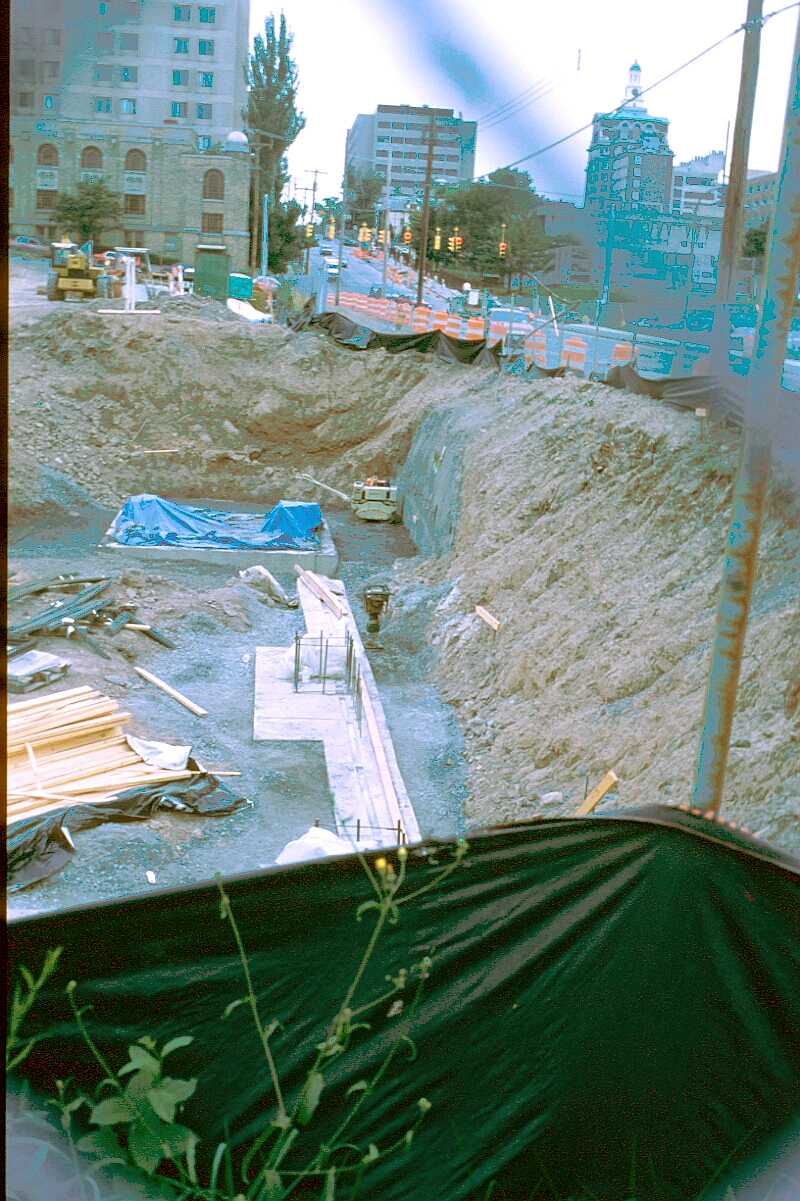

image 15: Nuclear testing apparatus.

The test equipment pictured in image 15 is used as the standard method of test for density of soil and soil aggregate in place by nuclear methods (shallow depth); approved by the American Association of State Highway and Transportation Officials (AASHTO), it determines the degree of compaction, soil density, and moisture content of compacted backfill material. Standards for these tests are established by the ASTM, AASHTO T 238-86, AASHTO T 239-86, and are a part of all construction documentation establishing backfill and compaction performance criteria.

Division 2

Page 6

Copyright ©2001

_____________

URL:

http://__________________/D2-6.htm