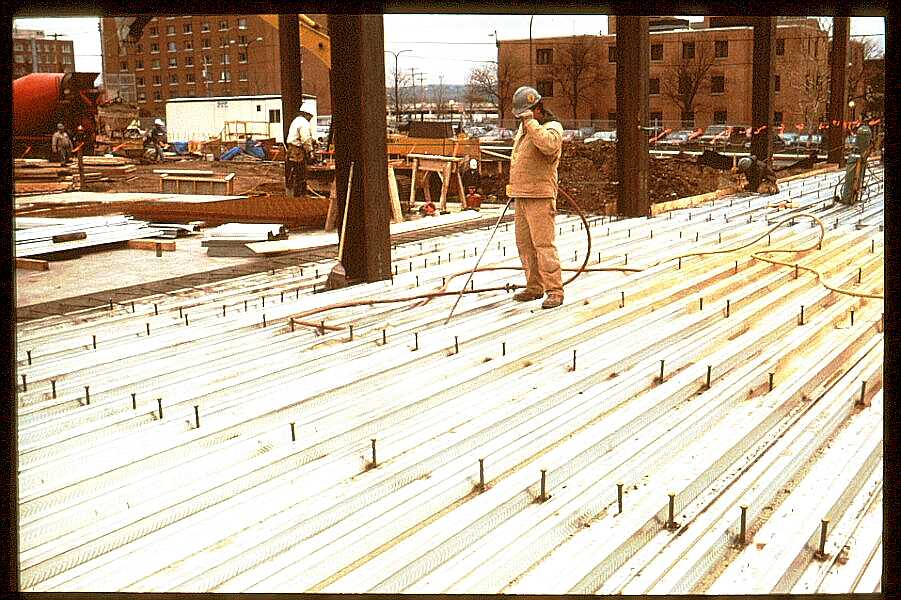

image 13: Composite slab construction.

Division 3 - Concrete

Section 00310 Concrete

Work

image 13: Composite slab

construction.

The super structure calls for a concrete and steel composite deck construction. The deck is a galvanized 20 gauge cold-formed steel composite deck, which will be covered with a concrete fill to the specified slab thickness. The composite nature of the concrete and steel structure relies on welding the deck, as well as steel studs, to the steel girders, beams, and joists below. The deck serves as tensile reinforcing for the concrete, in most cases, and is a lost form, which considerably lowers the cost of construction while eliminating a large amount of dead load.

Image 13 shows the corrugated steel deck, which has been puddle welded to the steel girders and beams below. The series of short uprights are steel studs, which have been welded, in a separate operation, through the steel decking to the beams and girders below. The studs therefore are an indication of where the steel structure is under the deck. The worker is cleaning the surface of debris prior to the installation of additional steel reinforcing.

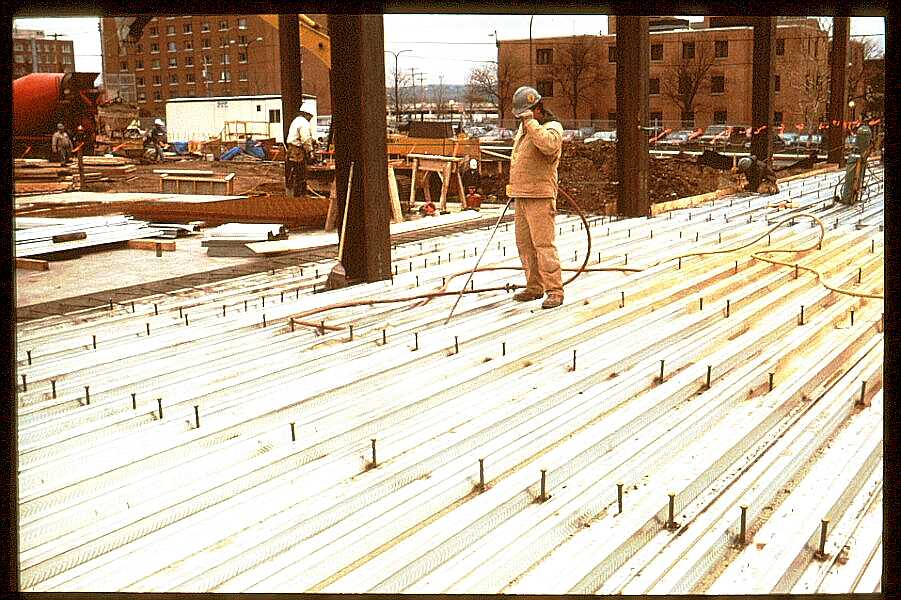

image 14: Slab pour stops.

The first floor slab is engaged with the foundation wall. Image 14 shows a pour stop form built to edge the concrete at the foundation wall. This will allow for concrete to fill in and around the steel column as well. Columns must therefore be set and plumbed prior to the final placement of concrete at this juncture.

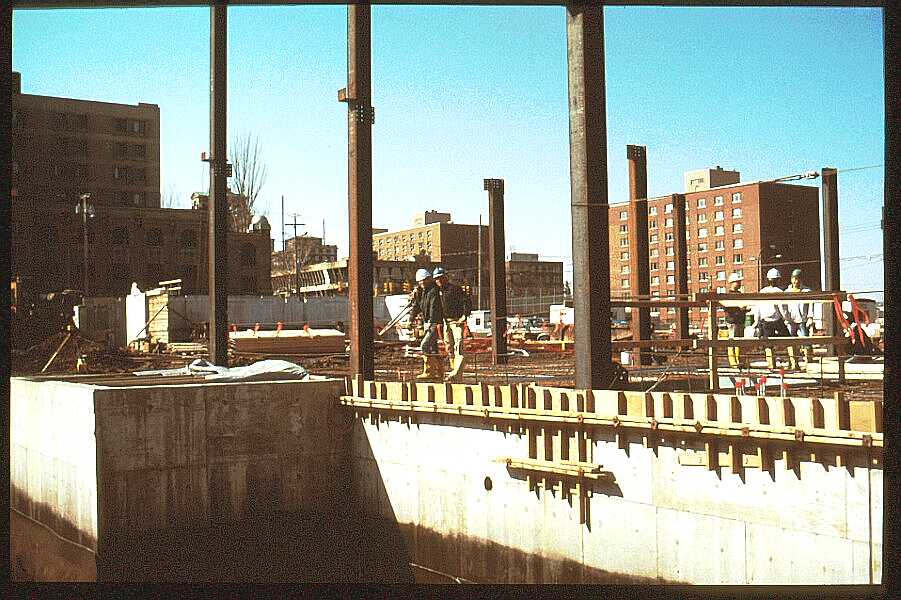

image 15: Slab edge and column base plate.

Another view of the first floor slab shows the pour stop form, dowels which have been bent to receive the slab, and a column base plate set for steel superstructure. Note the copper cable ground, which will be attached to the steel column when it is erected.

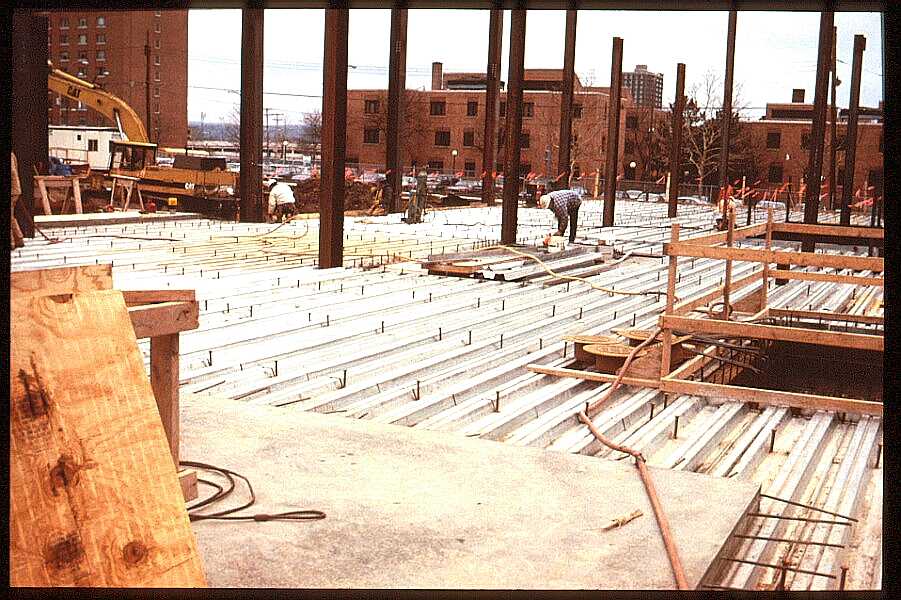

image 16: Checkerboard placement of concrete.

The slab in the foreground was placed and bullheaded off with dowels to receive the next section of composite slab concrete. The checker boarding of slab pours is a typical construction procedure that allows for sections of slab to be placed, as they are ready. This dynamic placement of concrete makes for an efficient and continuous labor and material use throughout the floor plate process.

image 17: Slab bulkhead at stair juncture.

The junction of a steel pan, concrete filled stair and a floor slab requires additional reinforcing steel to tie the two separate structures together. Note that bulkhead dowels have been bent into a hook with an additional reinforcing bar inserted. Steel studs will also be welded to the beam below prior to placing concrete into the pans of this stair. The steel pan acts as tensile reinforcement for the stair treads, platforms, and landings. Additional temperature steel mesh is added as top reinforcing just prior to the placement of concrete.

image 18: Reinforcing bar placement on composite steel deck.

In image 18 we see additional top steel reinforcing being placed on the deck at the column penetrations as well as a welded wire mesh which is temperature reinforcing. Note that this is a dropped section of floor slab which occurs at a loading dock at the first floor of the building.

Division 3

Page 6

Copyright ©2001

_____________

URL:

http://__________________/D3-6.htm