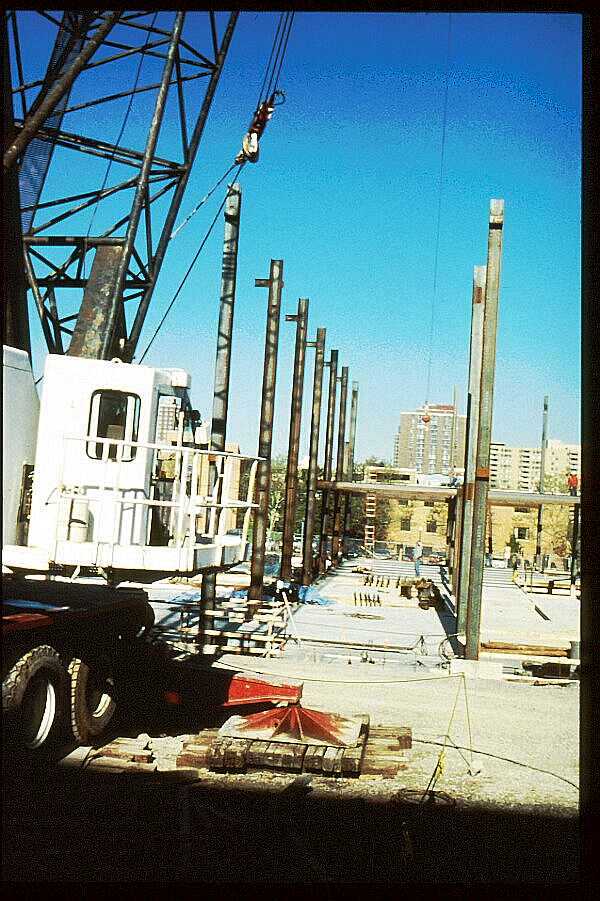

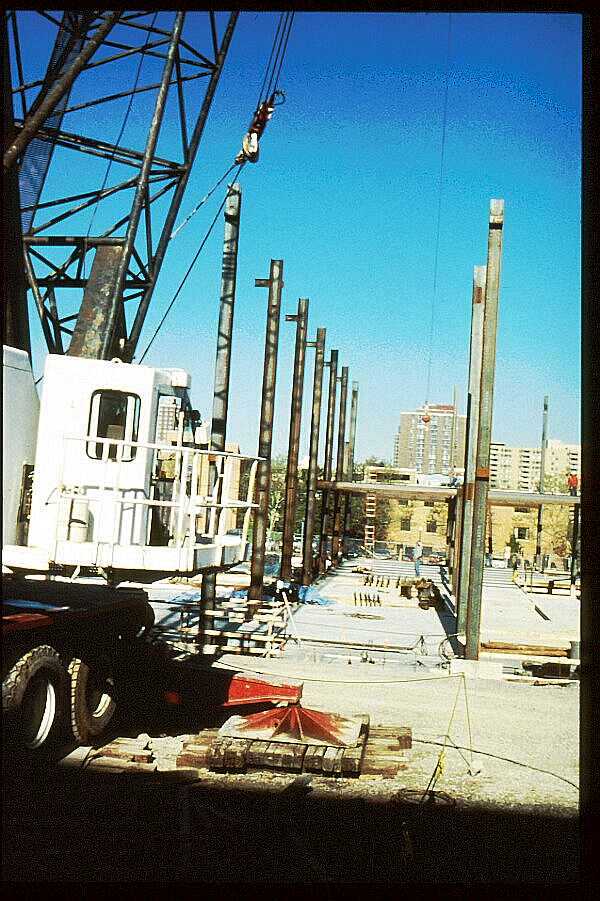

image 1: Structural steel erection.

Division 5 - Metals

Section 05120 Structural

Steel

image 1: Structural steel

erection.

Image 1 shows the initial erection of column steel, which is fabricated at two story lengths plus approximately 36" . The additional length of the first columns will allow for ease of splicing at the second floor (see image 2). Temporary steel cable is diagonally strung between columns to plumb the structure as the first story steel takes shape. The importance of checking and double checking the plumb and level of the initial column erection is imperative for any steel superstructure. A mistake of one second of a degree can be costly at the 7th floor of a building. Steel is erected by ironworkers, riggers, and crane operators.

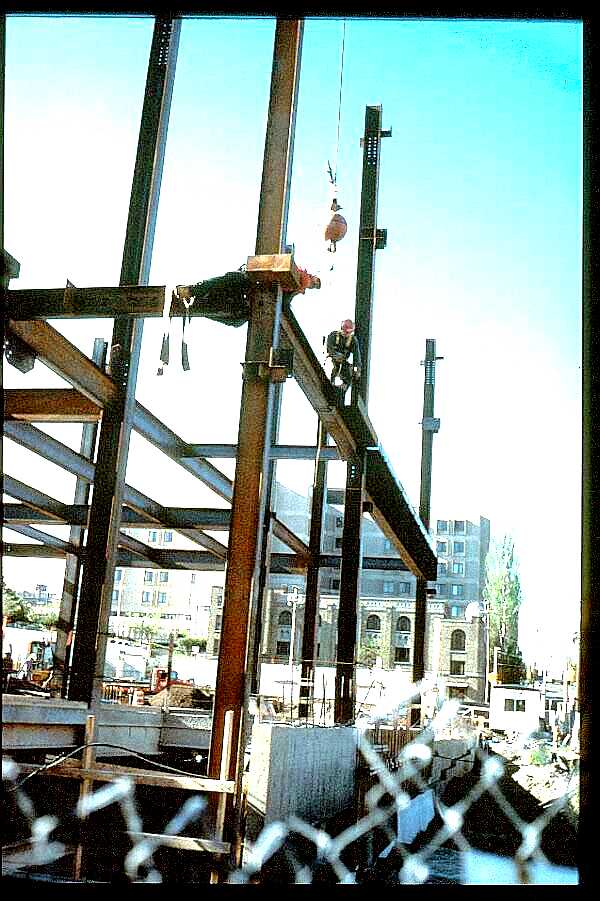

image 2: Steel erection.

This view shows a girder being guided into place by two ironworkers. Hard hats and safety harnesses are required at all times while steel erection is under way. It is a common procedure not to enter the building where steel is being erected until the steel erector has indicated that all steel is safed off and or bolted. Our honor classes, as well as all other trades on the job site, were kept out of harms way during steel erection. Note the steel pour stops for the composite steel and concrete slabs have been attached to the girders at the periphery of the floor slab at this elevation of the building.

Division 5

Page 1

Copyright ©2001

_____________

URL:

http://__________________/D5-1.htm